Development

hardware development

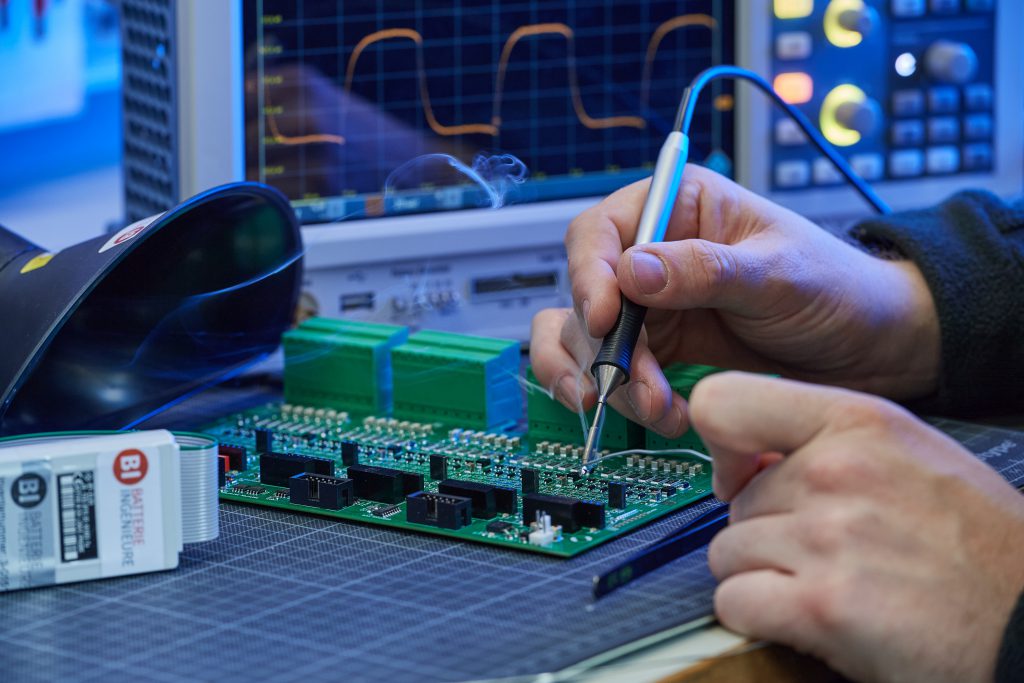

Very special tests of batteries and battery packs often require measurement electronics that are precisely matched to the test. Depending on the application, these may not be available on the market or their functionality may be limited. BatterieIngenieure GmbH is able to develop and use special measurement electronics exactly adapted to the test.

Especially for characterization and parameterization of algorithms, the simulation of a complex application-related load case is necessary. Pulse generators developed by battery engineers in the past have already proven theirselves here. These generate current pulses with a defined amplitude and frequency with low hardware effort, which are superimposed on a conventional charging circuit. In this way, pulses of up to a few amperes in the kiloheart range can be modulated to a constant current of over 1000 amperes.

In combination with the rest of the test bench, this replicates a vehicle electrical system sufficiently well so that elaborate tests in a real vehicle can be largely dispensed with for the development of the algorithms.

Intelligent battery sensors detect these pulses and are thus able to continuously determine the internal resistance of the battery. This is only one example from the resulting test spectrum for sensor and algorithm tests.

Another use case is the control of the tests depending on the test procedure.

Controls and methods have been developed to keep the surface temperature of the test specimen at a constant value instead of testing with a constant air temperature inside the climatic chamber.

With our knowledge, we can also offer assistance with your own hardware development, guiding you from the design of the battery and BMS to the testing of the finished battery pack.

The assessment of battery packs and protection electronics including electrical verification of the functionality of the protection function is also part of our spectrum.